SsGlu1A (exo-β-Glucosidase)

SsGlu1A

Ex-Glu0016

(EC.3.2.1.21) exo-β-Glucosidase

CAZy Family: GH1

PROPERTIES

1.ELECTROPHORETIC PURITY

-Single band on SDS-gel electrophoresis (MW ~57kDa)

Figure 1. Electrophoresis analysis of SsGlu1A. M, molecular weight marker (PageRuler Prestained Protein Ladder, Thermo Scientific); lane 1, culture lysate before IPTG induction; lane 2, culture lysate after IPTG induction.

2.SPECIFIC ACTIVITY

0.26 U/mg protein (on pNP-β-glu) at pH7.0 and 30°C

One Unit of pNP-β-glu activity is defined as the amount of enzyme required to release 1 μmol of glucose per minute from pNP-β-glu (5mM) in phosphate buffer(10 mM) pH7.0.

3.RELATIVE RATES OF HYDROLYSIS OF SUBSTRATES

Table 1. Relative activity of SsGlu1A on different substratesa

aAll the substrates were reagent-grade, and were used at 1 mg/ml.

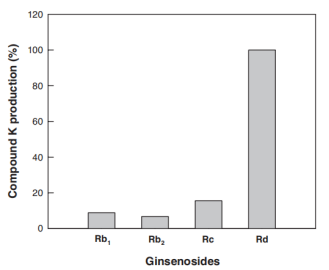

Figure 2.Compound K Production from Some Ginsenosides UsingSsGlu1A. The reactions were performed in McIlvaine buffffer (pH 5.5) at 85°C for 20 min using 0.1–1 U/ml of enzyme. At 100% relative production, 19.3 mmol/ml of compound K was produced for 1 min.

4.PHYSICOCHEMICAL PROPERTIES

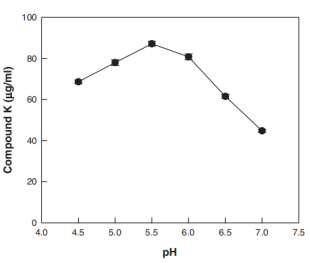

pH Optima:5.5

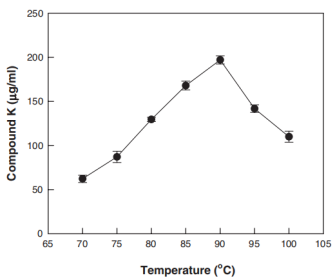

Temperature Optima:90°C

Temperature Stability:<85°C

Figure 3. Effffects of pH on Compound K Production UsingSsGlu1A. The reactions were performed in McIlvaine buffffer (pH 4.5–7.0) at 75oC with 5 U/ml enzyme for 1 h. The data represent the means for three separate experiments.

Figure 4. Effffects of Temperature on Compound K Production UsingSsGlu1A. The reactions were performed in McIlvaine buffffer (pH 5.5) with 5 U/ml of enzyme for 1 h. The data represent the means for three separateexperiments.

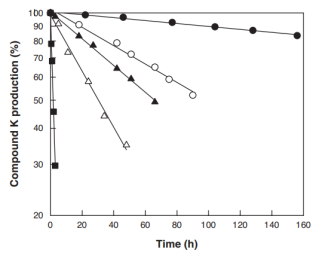

Figure 5. Thermal Inactivation ofSsGlu1Ain Compound K Production. The enzyme was incubated in McIlvaine buffffer (pH 5.5) at 70 (●), 75 (○), 80 (▲), 85 (△), and 90°C(■), and then compound K production was determined after reactions were performed in at 75°Cwith 5 U/ml of enzyme for 1 h.

5.STORAGE CONDITIONS

The enzyme should be stored at -20°C. For assay, this enzyme should be diluted in phosphate buffer (20 mM) pH6.0. Swirl to mix the enzyme immediately prior to use.

6. REFERENCES

[1] Kyeong-Hwan NOH, Ju-Wan SON, Hye-Jung KIM, et al. Ginsenoside Compound K Production from Ginseng Root Extract by a Thermostable β-Glycosidase from Sulfolobus solfataricus. Biosci. Biotechnol. Biochem., 2009,73 (2), 316–321.